Last Updated on August 2, 2023

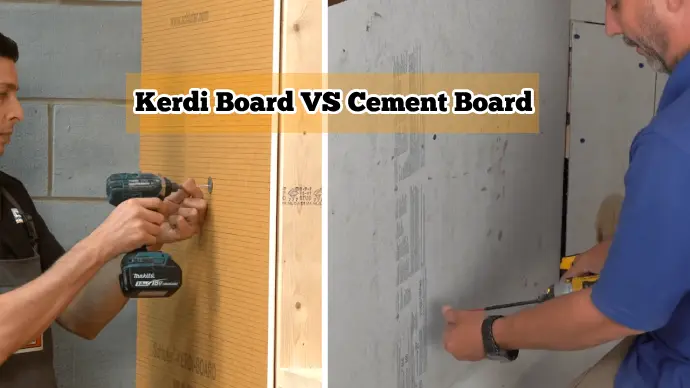

If you’re planning a bathroom renovation or building a new shower, you may wonder which type of backer board to use: the Kerdi board or cement board. Both have advantages and disadvantages, so it’s essential to understand their differences before deciding.

Kerdi board is a lightweight foam panel covered with a waterproof membrane on both sides. It’s designed specifically for wet areas like showers and tub surrounds, where moisture can cause damage over time.

Conversely, a cement board is made from cement and reinforced with fiberglass mesh and other ingredients. It’s also water-resistant but not completely waterproof like the Kerdi board.

Here, we’ll explore the differences between these two boards so you can make an informed choice for your project.

Difference Between Kerdi Board vs Cement Board

Kerdi board and cement board are common materials in tile installations, particularly in wet areas such as bathrooms and showers. While both materials serve as tile substrates, they differ in composition, installation process, performance and more. Differences between them include:

No 01: Composition

Kerdi board is a type of extruded polystyrene foam that is lightweight in nature. It is also waterproofed on both sides, making it inherently water-resistant.

Conversely, cement board is manufactured using cement and reinforcing fibers, which makes it denser and heavier than Kerdi board.

No 02: Waterproofing

Kerdi board incorporates a waterproofing membrane on both sides, providing excellent waterproofing capabilities without requiring additional steps.

In contrast, a cement board is not inherently waterproof and needs a separate waterproofing membrane to create a waterproof substrate. This means you must go through the extra step of applying a liquid-applied or sheet-type membrane before installing tiles or finishes on top of your cement board.

No 03: Installation

Regarding installation, there is a significant difference between the two options. One option is straightforward, while the other requires more labor-intensive work.

Kerdi board is relatively easy to install since it can be conveniently cut with a utility knife and attached to framing using suitable adhesives. On the contrary, cutting cement boards requires special tools, such as carbide-tipped scoring knives or power saws with masonry blades.

A cement board is screwed or nailed to the framing and reinforced with fiberglass mesh tape, which will then be covered with mortar.

Regardless of the option chosen, it is essential to seal the seams. Kerdi board requires a Kerdi band and thin-set mortar for this step, while cement board requires fiberglass mesh tape and mortar.

No 04: Weight and Thickness

Kerdi board is lightweight and comes in various thicknesses depending on your application needs. It’s designed to be easy to handle and install, making it a popular choice for DIY enthusiasts.

In comparison, cement boards are denser and heavier compared to Kerdi boards. It typically comes in standard thicknesses such as 0.25 inches (6 mm), 0.42 inches (10.5 mm), or 0.5 inches (12.5 mm). Maneuvering during installation is more difficult for larger loads or applications requiring extra strength.

No 05: Performance

Kerdi board is an exceptional choice for moisture-prone areas like bathrooms and kitchens due to its unmatched waterproofing and vapor management features. It boasts some insulation value that could improve your energy efficiency.

Alternatively, a cement board provides a robust foundation for installing tiles. Even though it requires extra waterproofing steps, it is often more affordable than the Kerdi board.

Comparison Table between Kerdi Board and Cement Board

| Aspect | Kerdi Board | Cement Board |

| Composition | Lightweight, foam-based panel with a waterproofing membrane on both sides (XPS) | The rigid panel made of cement and reinforcing fibers |

| Waterproofing | Inherent waterproofing with built-in membrane | Requires separate waterproofing membrane |

| Installation | Relatively easy to install. Cut with a utility knife, adhesive attachment, seams sealed with Kerdi band and thin-set mortar | Labor-intensive installation. Cut with special tools, attached with screws or nails, seams reinforced with fiberglass mesh tape and mortar |

| Weight and Thickness | Lightweight, various thickness options | Denser and heavier standard thicknesses are available |

| Performance | Effective waterproofing and vapor management, insulation value, higher cost | Stable and durable substrate, resistant to mold, mildew, and fire, requires additional waterproofing measures, cost-effective |

Is Kerdi better than cement board?

Regarding waterproofing options for tile installation, there’s no question that the Kerdi board outperforms the cement board.

The reason is simple: the Kerdi board has a built-in waterproofing membrane that eliminates the need for separate measures. Due to this, it offers excellent moisture protection and insulation value.

Another advantage of the Kerdi board over the cement board is the ease of installation. You don’t need any special tools or techniques. Instead, the board is lightweight and easily cut to fit any space. Its effectiveness means you’ll get a tile installation that lasts for years without problems.

Choosing the Kerdi board instead of the cement board will save you time, effort, and money. You’ll enjoy a waterproof surface that’s both durable and effective.

Choose the Correct Tile Substrate for Your Project: Cement Board vs. Kerdi Board

When choosing between Kerdi board and cement board as tile substrates, it’s essential to consider the specific needs of your project. A cement board is a reliable option in terms of durability and cost-effectiveness.

On the other hand, the Kerdi board outshines it with its integrated waterproofing membrane, easy installation, and insulation benefits. Particularly it benefits wet areas like bathrooms and showers, where moisture protection is crucial.

Ultimately, the decision between the two materials should be based on your priorities and budget and the nature of your tiling project. Regardless of your choice, both materials have unique advantages and can deliver sturdy, tiled surfaces if properly installed and maintained.