Last Updated on March 12, 2023

When it comes to drywall, the right tools can make all the difference. So it’s no surprise why professionals are leaving power saws behind for something much more dependable: a utility knife. This pocket-sized tool is convenient for cutting large sheets of wallboard, and it is perfect for small cornering jobs too.

But before you get started on the project of your dreams, it’s essential to understand how this process works (as well as any risks associated). With incorrect use, drywall could be damaged or worse. Also, an injury may take place, so don’t let that happen.

This post will take you through it all, from start to finish. Including how and where to cut, to common problems that pop up along the way.

How Can You Cut Drywall With a Utility Knife?

Materials Needed:

- Utility Knife

- Tape Measure

- Marker or Pencil

- Safety Goggles

- Drop Cloth or Plastic Sheeting

- Flat Level Surface for Cutting on

1. Measuring Accurately and Effectively

Taking measurements accurately and effectively is one of the key steps for cutting drywall effectively. Make sure to take measurements twice to get the most accurate results. It is also important to measure from one end of the piece to be cut, as well as at angles, to ensure that you will be able to make precise cuts.

When taking measurements, remember that drywall can be challenging to work with and so it is essential to plan to avoid errors or mistakes.

2. Marking Outlines on the Board with Pencil or Chalk Line

After measuring accurately and ensuring that the measurements are correct, the next step is marking out your lines on the drywall where you will make your cuts. Using either a pencil or a chalk line can help you create an outline for drywall cutting along.

3. Planning Ahead to Avoid Mistakes and Save Time

Planning ahead when slicing drywall with a utility knife is essential to save time and avoid costly mistakes. Consider any curves or shapes that might need carving before beginning any work with the utility knife.

This will help prevent you from having to redo any cuts due to incorrectly made lines or shapes. Additionally, it is crucial not to rush through any of these steps, as this could lead to inaccurate results and wasted time in the long run.

4. Positioning Yourself Comfortably For Optimal Control of the Tool

Making sure you are properly positioned for optimal control of your tools when cutting drywall is key for successful results. You should sit or stand comfortably so that you can control your tool when making precise, clean cuts on the sheetrock material.

Whether straight lines or circles/squares, without putting yourself at risk for injury due to awkward positioning or posturing.

5. Establishing Firm Pressure to Cut Through the Sheetrock Without Damage

Applying firm but gentle pressure while using a utility knife on sheetrock material is essential to achieve clean, precise cuts without damaging either your tool or the sheetrock itself. This can be done by holding your tool firmly while using slow yet steady strokes along your marked lines.

Be careful not to apply too much pressure, which could cause injury or breakage of either tool component (blade) or sheetrock material.

There may also be some differences in cutting sheetrock depending on which cut you are trying to make, a straight cut or curves/square. Here is what you need to do:

6. Making Straight Cuts Following The Lines Drawn On The Sheetrock:

Once all measurements are taken, outlines are marked out clearly, and proper positioning is identified before starting work. It is then time to move on to actually making straight cuts following those marked outlines on the board with a utility knife.

Again, it’s essential not to rush through this step as precision counts here greatly. Slowly running through each line, ensuring enough pressure yet avoiding breaking anything. There are key factors for success here, slow and steady wins the race.

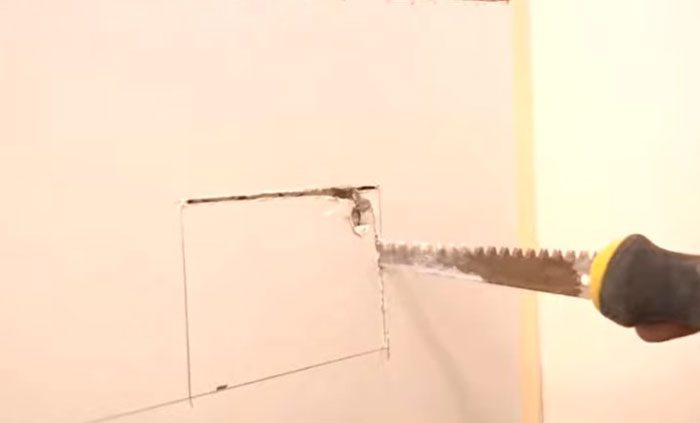

7. Making Curves or Squares Following the Outlines Marked On the Sheetrock:

Making curved shapes such as circles/squares also requires the same principles applied, just like described above when making straight line cuts. Then again, more attention must be paid to an even balance between speed and pressure applied during use.

Since curved surfaces require smoother execution due to their non-linear nature compared to linear/straight surfaces. This makes them more accessible handles than curved ones by nature (due to less speed required). Again patience & gradual application of force can lead to successful outcomes here too.

8. Finishing Up the Procedure For Clean and Neat Results

In the end, after finishing up all the other steps described above, we may need to refine our edges by rounding up corners & shaping the surface altogether for perfect results. This means applying extra pressure around edges, especially for sharper ones.

This can be done by lightening up on pressure applied around edges and then increasing the pressure slowly as you move towards the middle parts of cuts. This will give a neat, smooth finish to all our shaped surfaces, which will look finished & polished.

Advantages and Disadvantages of Cutting Drywall With a Utility Knife

It’s not hard to spruce up your home without breaking the bank, a utility knife can be an invaluable tool for making those essential cuts in drywall. Even so, it’s essential to consider both the advantages and disadvantages of using this tool for such a task.

Among the potential benefits and drawbacks are:

Advantages:

- Easier to manage than other drywall cutting tools

- Flexibility in terms of size and shape of cuttings

- Minimal drywall dust creation compared to power tools

- Easier to control than power tools

- More affordable than other tools

Disadvantages:

- Time-consuming

- Limited depth control

- Possibility of injury due to lack of power

- Limited depth and precision compared to other tools

How to Maintain Utility Knife After Working with Dry Walls?

Maintaining a utility knife correctly is essential after working with drywall, as it will ensure your safety, protect the blade and ensure you get the best results. Here are some tips:

Clean Your Blade Regularly: Be sure to remove any dust particles or other material that could get caught between the blade teeth. Rinse off any dirt buildup on both sides of the blade using warm water and a clean microfiber cloth.

Sharpen Your Blade Periodically: Remember to sharpen your utility knife blade periodically using a whetstone or honing stone. Follow the manufacturer’s instructions carefully to avoid damaging the blade’s edge when sharpening.

Position the Blade at an Angle: When cutting the drywall panel, hold your utility knife at an angle of 45° for best results. This will allow you to make precise, clean cuts without having to put too much pressure on the material as you cut. Also, the blade will last longer due to less pressure & stress during use.

Avoid Ripping the Paper Face of the Board: To prevent damaging the paper face of a drywall board, be sure to pull back on your utility knife slowly after each cut. Also, be careful not to move it too quickly from side to side while cutting through larger pieces of material.

Carefully Apply Pressure: You should always apply even pressure when making cuts with a utility knife for them to be accurate and consistent. This is especially true when dealing with thicker pieces of drywall that require more force than other materials for them to cut through effectively.

Use Multiple Blades: When working with thick materials, like a drywall sheet, it is a good idea to have more than one blade. This way, you will always have a sharp blade ready to use. During large projects, you won’t need to sharpen blades as often.

Does the Type of Utility Knife Affect the Ease And Accuracy of Cutting Drywall?

Yes, the type of utility knife can significantly impact how easily and accurately one can cut drywall. Different types of utility knives are designed for different purposes, such as heavy-duty or light-duty.

For instance, a longer blade with a thicker spine is typically better suited for heavy-duty tasks, while thinner blades with flexible spines are ideal for more precise cuts.

Aside from that, some knives come with specialized features that make them better suited to certain specific jobs, like cutting existing drywall. Some features of this knife are that it has ergonomic handles. This means the knife is easy to hold and won’t slip out of your hand.

There are also adjustable depth settings. Therefore, you can set the depth of the cut so you do not cut too deep or too shallow. And finally, the serrated edges help prevent slipping when cutting.

Some Recommended Good Quality Utility Knives for Cutting Drywall

If you’re looking to cut drywall like a pro, then get your hands on some good-quality utility knives. It’s true they make all the difference. Here are some suggestions you can consider:

Non-Retractable Heavy Duty Drywall Cutter

It’s perfect for cutting drywall quickly and accurately. It features a fixed-blade design that ensures stability and accuracy while cutting, as well as an anti-slip TPR grip handle for improved control and comfort.

The blades, constructed from high-carbon steel, are designed to be durable and long-lasting. This drywall cutter is perfect for both professionals and DIYers alike who need a reliable tool that can quickly make straight and accurate cuts in drywall.

Auto-Retractable Safety Utility Knife

Whether you’re doing chores around the house or DIY projects, this utility knife is just what you’re looking for. Crafted with a heavy-duty zinc-alloy body and SK2 high-carbon steel blades, this best utility knife is designed to last.

The non-slip TPR handle provides a secure and comfortable grip, while the self-retracting design increases safety. Also, the built-in blade storage allows for quick access to 4 spare blades stored in the handle.

Fixed-Blade Utility Drywall Knife

Using the grabber fixed-blade utility drywall knife is the ideal way to tackle a drywall project with a reliable and fixed utility blade. This simple and solid design is built to withstand repeated daily use, making it the ideal choice for any task or project.

With its ergonomic handle designed for easy gripping, you can complete jobs without the need to adjust your grip frequently. The durable carbon steel blade keeps a sharp straight edge and provides a smooth cut every time.

When Cutting Drywall With a Utility Knife, Do You Get Dust?

Using a utility knife on drywall creates some dust. This is because the blade of the utility knife cuts away tiny bits of drywall material as it passes through the surface. Despite this, compared to other methods, such as using an electric saw or rotary tool, the amount of dust created by a utility knife is significantly lower.

The dust particles can be very small and may float in the air for some time, so it’s essential to make sure you are working in an area that has good ventilation. Then, using a sharp blade will help reduce the amount of dust produced since it will create cleaner, more precise cuts.

Is There Any Risk of Damaging the Drywall By Using a Utility Knife?

No matter how careful you are with a utility knife, there’s always the potential for unintended consequences. When making cuts, excessive force can easily result in an expensive problem as deep cuts weaken drywall and threaten its structural integrity.

Moreover, if not used properly or handled carelessly, a utility knife’s sharp blade could injure someone or puncture walls filled with electrical wires. You need to be careful when you cut through drywall with a utility knife. To ensure that you are able to see what you are doing, ensure that the area is well-lit.

Get Done Quick and Cheap – Cut Drywall with a Utility Knife

Now you may know using a utility knife to cut drywall is a great way to save time and money when completing home improvement projects. It’s an easy-to-use tool that can make precise cuts quickly, making it a great option for those who don’t have access to power saws.

Still, safety must always be considered when using a utility knife, as there can be risks of damaging the drywall or getting injured. Follow the above mentioned steps and use the appropriate safety gear to ensure a successful and safe job.

So now that you know all about drywall cutting with a utility knife, why not give it a try? You won’t regret it.