Last Updated on March 13, 2023

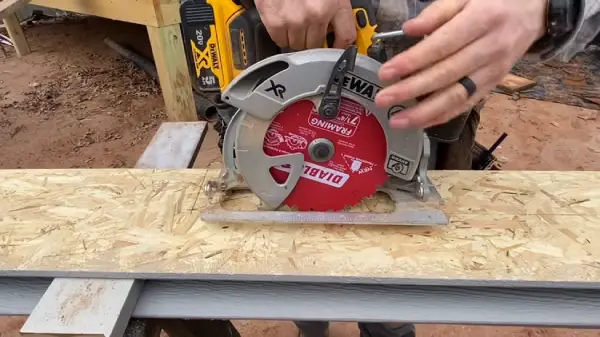

If you’re thinking of sprucing up your abode with some new drywall, you may be tempted to use the handy circular saw for quick trimming. Before taking on this DIY project, though, it’s essential to remember that while technically doable, experts don’t recommend using a circular saw as an effective cutting tool.

Cutting drywall with a circular saw creates a lot of unnecessary dust and debris that can be difficult to clean up afterward.

Also, it’s an inefficient way of making cuts because it takes more time and effort than using the right tools. We’ll discuss why drywall cutting with a circular saw isn’t ideal and what better alternatives you should use instead.

Can You Cut Drywall With a Circular Saw: Why Shouldn’t

Circular saws may carry more risks than necessary for drywall cuts, and people should understand the potential risks and safety concerns. With this in mind, below are several reasons to avoid circular saws.

1. Unnecessary Dust Clouds Created

When you use a circular saw on drywall, you can create an unnecessary amount of dust clouds that are both dangerous and difficult to clean up.

The saw blade itself creates friction when it cuts the drywall, which then generates heat and the sawdust particles become airborne.

These dust particles can travel into other parts of the house or into open windows, creating an unhygienic environment in its vicinity.

Also, these dust particles can damage furniture, electronics, and even carpets, leaving behind an unpleasant residue that is difficult to remove.

2. Dust Inhalation Health Hazards

Another reason not to use a circular saw is due to potential health hazards associated with inhaling the dust created by the sawing process.

Drywall dust comprises microscopic pieces of gypsum board and other materials, such as wood chips from nails and screws used to attach the drywall.

This type of dust contains silica, a known carcinogen that causes irritation of the eyes, nose, throat, and skin upon contact and inhalation into the lungs, which has been linked to lung cancer.

Long-term exposure can cause permanent lung damage or scarring that results in difficulty breathing or even asthma attacks in some cases.

3. Flying Objects or Kickback From the Saw Can Cause Injuries

The use of circular saws for drywall cutting has potential dangers associated with it due to flying debris from drywall pieces as well as kickback from the saw itself during operation.

Flying debris from drywall pieces cut by a circular saw can cause serious injury if someone stands too close to where the material is being cut.

Due to its powerful motor and spinning blade speed, kickback from the saw can also cause serious injury if it’s not properly controlled and monitored.

There are always risks involved with operating power tools like this so it’s important for operators to always wear appropriate safety gear, such as protective eyewear and gloves, while operating them at all times.

4. Complications from Poor Visibility Due to Dust Clouds

The dust from a circular saw can also create complications when cutting drywall due to poor visibility resulting from the dust clouds created by the tool.

As the air becomes more filled with drywall dust particles, it becomes increasingly difficult to see what you are doing while cutting through the material.

Not being able to see clearly while cutting can result in mistakes such as cutting into electrical wiring or making crooked cuts that won’t fit with other pieces of drywall.

Poor visibility caused by drywall dust clouds can also lead to an increased risk of injury due to the inability to see where your hands are while operating the tool.

5. Poor Line Control and Accuracy

Another issue that arises with using circular saws for drywall is poor line control and accuracy when cutting through the material. When utilizing a circular saw, it often takes several passes for one cut to be completed properly due to the uneven edges left behind after each pass.

This means that for straight lines or angles to be achieved accurately using a circular saw, multiple passes must be made, which takes much longer than simply using other tools, such as jigsaws or reciprocating saws, which offer better line control and accuracy during operation.

Even when taking multiple passes with a circular saw, there is still no guarantee that you will get perfectly straight lines or accurate angles, as these tools do not provide very good feedback on how even your cuts are going.

6. Risk of Splintering, Tearing, and Cracking

A further risk associated with circular sawing drywall is that it has the potential to cause splintering, tearing, or cracking along its edge if done improperly or with an incorrect blade type.

The speed at which a circular saw operates means that it is far easier for these mistakes to occur compared with hand tools if inexperienced operators use them carelessly.

These types of damage can decrease structural integrity and leave unsightly marks that would require extra effort when replacing or repairing sections of the wallboard later down the line.

7. Limited Mobility, Especially When Making Complex Cuts

Due to its size and shape, a circular saw does not offer the same mobility as other tools, such as jigsaws, when making complex cuts in drywall.

This limits the ability of the user to make precise curves and angles when using a circular saw on drywall. This makes it less desirable than other tools for intricate cuts.

A circular saw’s blade isn’t adjustable like some other tools, so it can be hard to make shallow or deep cuts.

8. Safety Concerns When Working Near Electrical Components

A major safety concern arises when using a circular saw near electrical components. If these blades come in contact with exposed wiring or other flammable materials near the work area, they could cause an electrical fire.

The blades themselves are very sharp and risk serious injury if handled incorrectly or without proper protective equipment, such as gloves and protective eyewear.

Because of these potential hazards, you really need to exercise caution when working in these types of environments with a circular saw.

9. Noise

Circular saws are known for being quite loud when in operation due to their fast-spinning blades and powerful motors. This noise pollution not only disrupts normal activities in the vicinity but can also cause hearing damage over time if proper precautions are not taken while operating one.

You need to wear ear protection while using these tools. This will help reduce the noise levels involved during use.

What Other Tools Can Be Used In Place of a Circular Saw for Cutting Drywall?

A handheld drywall saw, jab saw, utility knife, oscillating multi-tool, and reciprocating saw are all great alternatives to a circular saw when it comes to cutting drywall.

The teeth on a handheld drywall saw are angled in a way that makes it easy to cut through the wallboard. Utility knives are great for making the straight cut in drywall and can be used quickly and easily.

Oscillating multi-tools are versatile tools that allow you to make not only straight cuts but also more intricate cuts, such as curves and circles. Lastly, reciprocating saws use their rapid back-and-forth motion to cut through tough materials such as drywall with relative ease.

What Tool Do You Need to Use When You Cut Round Holes In Drywall?

A hole saw cutter is the best option when making a round hole in a drywall panel. Hole saws consist of a cylindrical metal blade that attaches to an arbor shaft, which is inserted into a power drill or drill press.

The sharp teeth of the hole saw cut through the material as it rotates around its center point, creating smooth round edges on both sides of the wallboard.

An adjustable hole cutter may be necessary for larger openings such as electrical boxes instead of a standard hole saw due to its ability to create larger diameter holes without changing out blades or bits.

Is It Possible to Use a Jigsaw When Cutting Drywall?

There’s no doubt that jigsaws are better for cutting through drywall sheets since they’re more precise and controllable.

Jigsaws have a blade that goes up and down. This blade lets users cut shapes and curves easily. There is also less dust and dirt when using a jigsaw than when using other tools like a handheld tool or circular saw.

It’s important that the correct size and type of jigsaw blade is selected based on material thickness and desired result before attempting any type of cut to ensure clean edges around your project piece and for safety purposes.

What Reciprocating Saw Blade Cuts Drywall?

When looking for a blade that will effectively cut through drywall material with ease and precision, opt for a 12-teeth-per-inch (TPI) carbide-tipped blade designed specifically for cutting wood materials such as plywood and other paneling boards.

These blades should operate well with most standard reciprocating saw models on the market today. They will provide clean edges whether you’re making straight or curved cuts into your wallboard material.

Also, these blades tend to be quite durable due to their carbide build quality, meaning they won’t break down after repeated uses like some other lower-quality blades might do.

Rest Easy: Keep Safe When Cutting Drywall

When cutting drywall with a circular saw, numerous amounts of dust and debris can be created in no time. Instead, opt for tools designed specifically to cut drywall, such as handheld drywall saw, reciprocating saw jigsaw or utility knife.

Also, ensure you keep safety at top-of-mind when operating any cutting tool by taking proper precautions, so your space remains protected from any unnecessary damage.