Last Updated on January 21, 2023

Reinforced concrete is a construction material made of steel bars or wire mesh, usually embedded in poured concrete. Rebar provides tensile strength to the hardened concrete, and it is an essential component for high-rise buildings. It also has applications in bridge building, water retention structures, and other uses where there are large compressive forces on the system.

Although rebar is a solid material, it is not impervious to damage. If you need to drill through rebar in concrete, there are a few things you need to take into account. This article will show you the ultimate guide on how to drill through rebar in concrete.

What You Will Need?

To drill through rebar in concrete, you will need the following tools:

- A power drill with a hammer function

- A concrete drill bit

- A rebar cutter

- Safety goggles

- Gloves

- Dust mask

How to Drill through Rebar in Concrete: Step-by-Step Guide?

Here is a step-by-step guide on how to drill through rebar in concrete:

1. Put On Your Safety Gear:

Before you start drilling, it is essential to put on your safety gear. This includes gloves, safety goggles, and a dust mask. If you have long hair, you should tie it back to avoid it getting caught in the drill.

2. Select the Right Drill Bit:

The type of drill bit you will need depends on the diameter of the rebar. If the rebar is less than ½ inch in diameter, you can use a carbide-tipped masonry drill bit. For a rebar that is between ½ inch and ¾ inch in diameter, you will need a hammer drill with a carbide-tipped masonry drill bit.

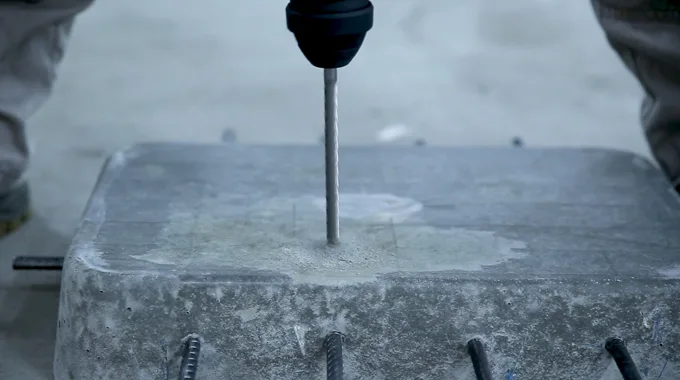

3. Set the Drill to Hammer Mode:

If your drill has a hammer function, make sure it is set to “hammer mode” before you start drilling. This will prevent the drill bit from slipping on the rebar.

4. Start Drilling:

Position the drill bit on the concrete surface and start drilling. Apply gentle pressure to avoid breaking the drill bit. When the drill bit starts to penetrate the rebar, you will feel a sudden increase in resistance.

5. Cut the Rebar:

Once the drill bit has penetrated the rebar, you will need to cut it. You can do this with a rebar cutter or a pair of bolt cutters. It is important to make a clean cut so that the rebar does not become a trip hazard.

6. Remove the Rebar:

Once you have cut the rebar, you can remove it from the hole. You may need to use a pair of pliers to grip the rebar and pull it out.

7. Clean Up the Hole:

Once the rebar has been removed, you can clean up the hole with a wire brush. This will remove any concrete debris that may have become lodged in the hole.

8. Remove Your Safety Gear:

Once you have finished drilling through the rebar, remove your drill bit and safety gear. Please wash your hands thoroughly to remove any concrete dust that may have gotten on them.

What is the Best Bits for Drilling through Rebar?

A few different types of drill bits can be used to drill through rebar. Here is a look at the best bits for drilling through rebar:

1. Diamond-Core:

Diamond core drill bits are the best drill bit for drilling through rebar. They are made of a steel tube that is filled with diamond particles. The diamond particles provide a cutting edge that can easily penetrate concrete and rebar.

2. Carbide-Tipped:

Carbide-tipped drill bits are also suitable for drilling through rebar. They are made of a steel tube that is filled with carbide particles. The carbide particles provide a cutting edge that can easily penetrate concrete and rebar.

3. Masonry:

Masonry drill bits are also good for drilling through rebar. They are made of a steel tube that is filled with carbide or diamond particles. The carbide or diamond particles provide a cutting edge that easily penetrates concrete and rebar.

4. Rebar Cutter:

A rebar cutter is a tool that can be used to cut the rebar. It looks like a pair of pliers with two cutting blades. The cutting blades are carbide or diamond and can easily cut through rebar.

5. Steel Twist Bits:

Steel twist bits are also suitable for drilling through rebar. They are made of a steel tube that is filled with carbide or diamond particles. The carbide or diamond particles provide a cutting edge that can easily penetrate concrete and rebar.

Some Tips and Suggestions:

Here are some tips and suggestions to help you drill through rebar:

1. Always wear safety gear when drilling through rebar. This includes gloves, safety goggles, and a dust mask.

2. Start with a small diameter drill bit and work your way up to a larger diameter drill bit.

3. Use a hammer drill if available. If not, use a regular drill and apply gentle pressure to avoid breaking the drill bit.

4. When cutting the rebar, make sure to make a clean cut. This will prevent the rebar from becoming a trip hazard.

5. Use a wire brush to clean up the hole once the rebar has been removed. This will remove any concrete debris that may have become lodged in the hole.

6. Wash your hands thoroughly after drilling through rebar to remove any concrete dust that may have gotten on them.

FAQs

Will a Core Bit Go Through Rebar?

The holes can be placed wherever convenient with core drills because they cut quickly through rebar. For installing plumbing, electrical, and HVAC systems, holes can be drilled of almost any diameter up to 60 inches in diameter.

What Size Is 10m Rebar?

Typical 10M rebar diameter is 11.3mm (or 0.45 inches), rounded to 10mm (resin diameter 1,35mm). Dimensionally, 10M rebar has a nominal diameter of 10.3 millimeters (1.35 inches), and thus the size or diameter of 10M rebar is 11.3 millimeters.

Conclusion

Having drilled a hole through concrete rebar, you are now capable of quickly creating a lot of different openings for plumbing, electrical, and HVAC systems. All you need to do is make sure that you are wearing safety gear when doing the drilling. Don’t be tempted to drill around the hole and then leave it untouched so that it will not create a trip hazard. Thanks for reading.