Last Updated on January 20, 2023

For every handyman, a hammer is one of the most basic tools in their arsenal. It is versatile and can be used for a variety of tasks, from driving nails to prying things apart.

The handle is an integral part of the hammer, and its design can have a major impact on the usability of the tool.

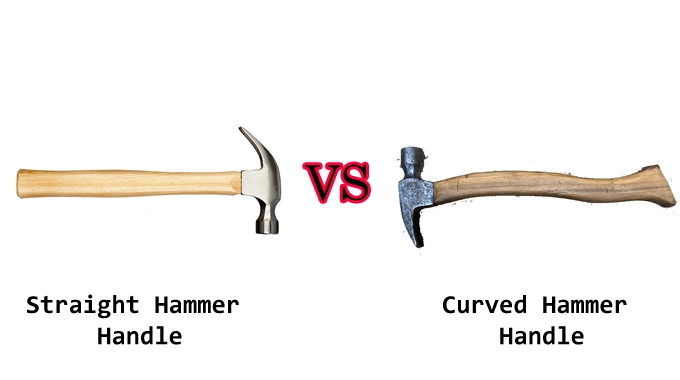

Straight and curved handles are the most commonly found designs for hammers. Each design has its own advantages and uses.

You should be familiar with the differences concerning straight vs curved hammer handle so that you can make the optimal choice for your needs.

Most Common Types of Hammers

Before we get into the discussion of the straight and curved hammer handles, let’s take a look at the major types of hammers that you are likely to encounter.

1. Claw Hammer

This is the most widely used hammer, and it is characterized by its two-sided head. In a claw hammer, one side features a flat surface that is suitable for pounding nails, while the other side has a curved claw capable of pulling nails out of wood or other materials.

2. Ball-Peen Hammer

Known as a machinist’s hammer, a ball-peen hammer has a round head and a flat head, with different purposes. The round head is used for rounding off corners or creating indentations, while the flathead works by flattening surfaces.

3. Framing Hammer

The framing hammers are designed for use in framing applications. It has a long wood handle that provides extra leverage, and the head is usually heavier than that of a straight claw hammer. California framer is one popular type of framing hammer.

4. Club Hammer

The club hammer, sometimes referred to as a lump hammer, is a tool used for breaking up bricks and concrete.

It consists of a heavy head, usually made of steel, with a wooden or plastic handle. Typically, the head is rectangular or pear-shaped, with one flat side for striking and one curved side for chiseling.

5. Sledge Hammer

As the name implies, a sledgehammer is a large hammer with a long handle designed for breaking up thick materials such as concrete and stone. It is also useful for driving nails or stakes into the ground.

Similarities Between Straight and Curved Hammer Handle

Although hammers come in a variety of shapes and sizes, they all have one thing in common: a handle.

While these handles may look different at first glance, they actually share a number of similarities. Below, we will discuss some of the most notable similarities between the two handle types.

1. Holding the Hammer

The primary similarity underlying straight and curved handles is the way in which they are held.

In both cases, the handle is designed to be gripped with one hand near the base and the other hand closer to the hammer’s head. This grip provides stability and leverage when swinging the hammer.

2. Balance

Each type of handle is designed to be balanced so that the head’s weight is evenly distributed.

This helps to ensure that the hammer does not slip out of the user’s hand and allows the user to control the tool.

3. Material

The vast majority of hammer handles are made from wood, although some may be made from metal or plastic. Wood is the most popular choice because it is strong and durable, but it can also be replaced if it becomes damaged.

4. Length

Another similarity between straight as well as curved hammer handles is their length. Most hammer handles are about 14 to 18 inches long, although there are some that are shorter or longer.

This length provides the user with enough leverage to swing the hammer with force but is not so long that it becomes unwieldy.

Key Differences Between Straight vs Curved Hammer Handle

After looking at some of the common characteristics associated with each type of handle, let’s now take a closer look at the key differences.

Knowing the key differences will help you determine which type of handle is most suitable for your needs. As a result, you’ll be able to get the most out of your hammer.

1. Shape

The shape of the hammer handle is important for two reasons. First, it affects the overall balance of the tool. A well-balanced hammer will feel comfortable and good in your hand and will be easier to control.

Second, the handle’s shape affects how much force is transmitted to the hammer’s head when you hit a nail. One of the primary differences between these two types of handles is their shape.

As the name suggests, a straight handle is perfectly straight, while a curved handle has a bit of a curve to it.

This may not seem like a big deal, but it can actually make a big difference in how the hammer feels in the hand as well as how effective it is at driving nails or prying things apart.

2. Uses

Though both curved and straight hammer handles offer benefits, they are best suited for different tasks. Straight handles are better for precision work since they provide a clearer line of sight between the hammer’s head and the target.

This is especially important when working with small nails or delicate materials. Meanwhile, a curved handle is better suited for continued use, as it helps to reduce fatigue in the wrist and forearm.

The added leverage also makes it easier to drive larger nails or bolts. As a result, it is important to select the right type of hammer handle, depending on the task at hand. With a little bit of forethought, any project can be completed with ease.

3. Grip

As a hammer is used to hit objects, the way it is held is important for both safety and accuracy. A good grip will help to prevent the hammer from slipping while also ensuring that the blow is delivered directly to the target.

The shape of the handle can have a big impact on the grip. For example, a curved handle provides a more natural grip for the hand, while a straight handle may require the user to adjust their grip.

This is something to keep in mind when choosing between a curved and straight hammer handle.

4. Balance

Both safety and accuracy depend upon the balance of the hammer. If you don’t have the handle balanced properly in your hand, it can slip and cause you to lose control.

This can not only lead to accidents, but it may also damage the material you’re working on. In terms of balance, a curved handle has an advantage over a straight handle.

Due to the curvature of the handle, the head’s weight is balanced. As a result, the hammer feels more stable in your hand and is easier to control.

5. Aesthetics

While functionality is the most important consideration when choosing a hammer handle, aesthetics can also be a factor. There are some people who value the way their tools look as much as the functionality they provide.

Curved handles are often seen as more elegant, while straight handles have a more rugged look. In the end, it’s up to each individual to decide which handle design is more aesthetically pleasing to them.

However, it’s worth considering how the look of your hand tools can impact your mood and overall well-being.

Straight Vs Curved : Which Hammer Handle is Right for You?

Now that you know the key differences pertaining to these two types of hammer handles, it’s time to decide which is the best hammer for your needs. Both types of handles offer different advantages.

Ultimately, the best type of handle depends on your own preferences and the project you’re working on. In order to perform delicate work with more precision, a straight handle is a way to go.

However, if you’re looking for a handle that is more comfortable to use and provides greater leverage, a curved handle may be the better option.

For those who are doubtful about which handle will work best for them, it’s always wise to try both before making a purchasing decision.

Whichever type of handle you choose, make sure it feels right in your hand that provides the right amount of balance for the task at hand.

Frequently Asked Questions:

There are a few questions that people often have about hammer handles. Here are some of the most frequently asked questions, along with their answers.

1. What Makes a Good Hammer Handle?

A well-designed hammer handle should provide a comfortable grip, good balance, and durability. The best way to achieve these qualities is to select a material that is strong yet lightweight.

2. How Do You Measure a Hammer Handle?

A hammer handle’s length is typically measured from the end of the handle to the point where it meets the head. The width of the handle is typically measured at its widest point.

3. What Is the Weight of a Hammer’s Head?

Depending on the type and size of the hammer, the weight of the head can vary. On average, the head weighs between 16 and 22 ounces.

4. What Is the Life Expectancy of a Hammer Handle?

The longevity of a hammer handle depends on the material it is made from and how it is used. Generally speaking, a well-made hammer handle can last for many years with proper care.

Conclusion

When it comes to straight vs curved hammer handle, there is no clear winner. It all depends on the individual preferences of the user.

We hope you have understood the key differences relating to these two types of handles after reading this article. Next time you decide to purchase a new hammer, you can make an informed decision about which handle type is right for you.

Relevant Article: