Last Updated on March 5, 2023

Installing wallboards is one of the most tedious tasks for home or commercial construction projects. It requires manual lifting, carrying, and positioning large drywall panels for walls in awkward positions and difficult-to-reach places. But can a drywall lift be used for walls for a faster, more efficient installation?

A drywall lift is an ideal tool for easily maneuvering hefty wall sheets or plasterboards. With its adjustable features, you can get an impeccable finish in even the tightest spaces. Be sure to double-check your setup first and follow all instructions.

With the right setup and following directions carefully, your walls will be transformed into works of art. Read on to learn how to use a drywall lift for your wall installation project.

How Can a Drywall Lift Be Used For Walls: DIY Steps

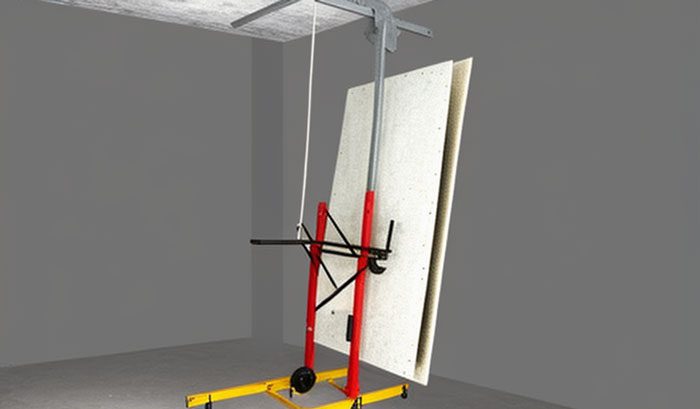

A drywall lift can be a great tool for installing walls, ceilings, and panels. It allows you to easily maneuver heavy panels into position and hold them securely while secured with screws or nails. Here are a few steps on how to use a drywall lift properly:

Step 01: Setting Up the Drywall Lift

To set up the drywall lift, begin by unfolding it and ensuring that each of its legs is securely locked. A locking feature is usually included in the design of the lift to prevent any accidents from occurring.

Once standing, adjust the collar clamps so that the sheetrock can be easily secured onto the lift. Check for any loose parts or broken pieces before continuing with the setup. Make sure all locks are firmly engaged and that there is no movement when inserting a panel.

Step 02: Positioning the Lift on the Wall

After setting up the drywall lift, position it on the wall. To do this, carefully calculate how much leverage and weight needs to be distributed onto the wall while also considering height restrictions and available space.

Once determined, push against the wall with slight pressure and easily secure using a lever provided in most lifts. This helps to distribute weight evenly and ensure optimum stability throughout the installation process.

Step 03: Inserting Sheetrock Panels onto Lift

Once positioned on the wall, begin inserting sheetrock panels onto the platform. Gently insert the panel with both hands while maintaining balance and control with collar clamps provided in most models of lifts. Do not force the panel, as it may break or shatter upon doing so.

Instead, put the panel onto the platform. Make sure it is spread across the platform, so it is safe when the lift moves it up to the ceiling or other high places.

Step 04: Transporting Sheetrock Panel to Desired Location on Wall

When transporting the sheetrock panel to the desired location on the wall, use the drywall lift platform to tilt it back until it is fully engaged and in complete contact with the wall surface. This helps to ensure that the panel will stay securely in place during transit.

Second, use the leverage arm provided with the lift to push the panel forward and transport it to the desired position. It may be necessary to use your body weight or other objects, such as a block of wood or a heavy-duty dolly, to help move large or heavy panels.

To help keep them from slipping, you can also secure these items with duct tape or other adhesive material before attempting any movement.

Step 05: Securing The Sheetrock to The Wall With Nails or Screws

Once you have safely transported your sheetrock panel into place, you need to secure it firmly against the wall with nails or screws for maximum stability and security.

Start by hammering nails into the studs around the edge of your sheetrock. Then drive in screws around the edge of the plasterboard. Make sure that all of the nails and screws are tightly secured before you move on to any finishing steps, such as taping, mudding, and texturizing.

You may need a drill for this part if you don’t want any nail heads visible after securing your sheetrock panel onto the wall. Use one drill bit size smaller than that of your fasteners so that they fit snugly into each hole without causing damage.

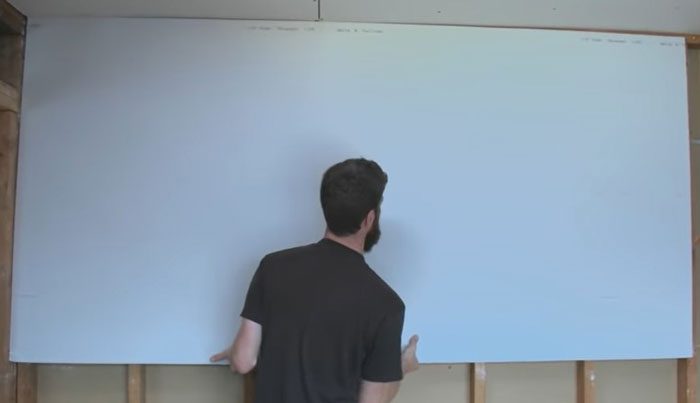

How Do You Hang Drywall on a Wall by Yourself?

Hanging drywall on your own can be a challenging task. The most important tool you will need is a drywall lift. This specialized piece of equipment helps to take the weight off your hands and arms, allowing you to hang drywall easily and efficiently.

You’ll also need to ensure you have the right screws, nails, or other fasteners to secure the panels to the studs behind the wall. Also, for added support, use joint compound (commonly referred to as mud) on all of your seams and joints.

To ensure your walls stay level and even when hanging the sheets, use a laser level or chalk line. Following these steps will help make it easier to create a professional-looking finished product when hanging drywall alone.

You can install drywall on a wall yourself with these ideas:

11 FT Drywall Lift Panel

This drywall lift panel is an incredibly versatile tool for any home improvement project. It can reach up to 11 feet and is perfect for lifting and suspending large drywall sheets or plasterboards. The ergonomically designed handle makes it easy to maneuver around, even in tight spaces.

This lightweight and durable product can save time and energy when completing big jobs like ceiling repairs or installing a new wall. With its adjustable height and locking mechanism, you’ll get a secure fit every time.

Drywall Rolling Lifter Panel

This is an advanced tool designed to help you move heavy-duty materials with ease. This panel lifter comes with 3 or 4 heavy-duty caster wheels that make transporting drywall over large distances a breeze.

The strong steel frame is built to last, while the adjustable height lever allows you to adjust the panel’s height quickly and easily.

Drywall Lift Rolling Panel Hoist Jack Lifter

This lifter is incredibly powerful for handling heavy-duty materials such as drywall panels or plywood boards. This hoist jack features an adjustable base with four swivel casters that make moving panels from one point to another a breeze.

Its durable steel construction ensures maximum stability, while its integrated hydraulic system provides smooth lifting action with minimal effort from the operator.

Why Shouldn’t You Hang Drywall Vertically With a Drywall Lift?

When using a drywall lift for installation, it is essential not to hang the panels vertically. When hung vertically, it does not allow you to hide any uneven studs behind the wall, which could cause an unsightly seam or bump in your finished wall.

If multiple panels are used in one area with any unevenness present, this could cause an exaggerated seam that would be difficult to repair once completed.

Hanging horizontally allows you to better correct any imperfections before adding joint compound so that it results in a professional-looking job when finished.

How High Can a Drywall Lift Reach For Installing a Wall?

A drywall lift can typically reach heights of up to 16 feet with ease when used correctly. Most lifts are designed to fit through standard door frames and be transported into higher areas, such as ceiling installations, with ease if necessary.

It is essential to always follow the safety rules when using these machines. If you do not use them according to the manufacturer’s instructions, people could get hurt or something could break.

How Much Can Sheetrock Walls Support Drywall Lift?

Drywall lifts are also designed on walls made from sheetrock, but how many sheets can they handle at one time? The size and weight of each sheet of sheetrock can be different.

To ensure that people don’t overload the sheetrock and cause it to break, manufacturers put maximum weight limits on their products. This limit can be different depending on the model number, but it is usually between 55 and 130+ pounds per panel that can be lifted at one time without causing any problems.

Therefore, depending on the size and thickness, multiple panels can usually be handled safely by these machines. Follow the recommended load capacity limitations every time you use the machine for the best results.

Experience Countless Benefits of Installing Walls with a Drywall Lift

Installing walls with a drywall lift can provide countless benefits compared to other methods.

Firstly, it ensures that all movements are safe throughout the process and require minimal effort from the user. And it makes transporting large sheets of sheetrock much easier while allowing them to be maneuvered into tight spaces.

Finally, with proper setup and positioning, they are reliable tools that will help make any wall installation job go smoothly. So if you’re considering installing a wall soon, why not try a drywall lift?