Last Updated on September 13, 2023

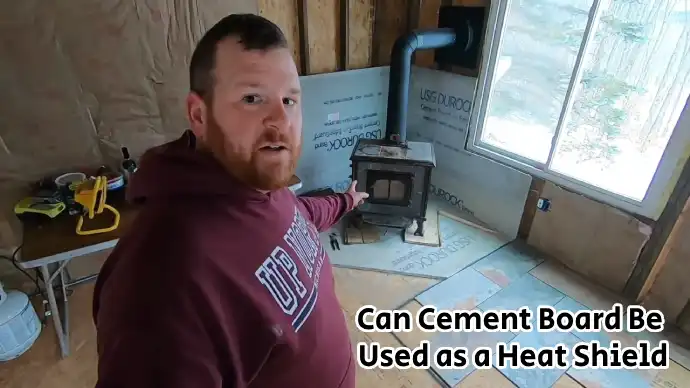

Cement board has emerged as a remarkable solution for heat shielding in various applications. This amazing building material is resilient against heat and has thermal resistance properties, transforming it into an ideal choice for safeguarding walls and floors.

Whether you’re considering the installation of a wood-burning stove, or a fireplace, cement board proves to be a reliable and effective heat shield.

Listen up before you slap that cement board up as a heat shield. While it’s pretty tough and can handle the heat, it’s not invincible.

So, don’t let it get too close to flames or embers. Let’s get into how to install the cement board as a heat shield.

How to Install Cement Board as a Heat Shield? Steps to Follow

The quick steps for installing heat insulation with cement board are:

Step #2: Mark the Cement Board

Step #3: Apply Construction Adhesive

Step #4: Position the Cement Board

Step #5: Secure the Cement Board

Step #8: Paint or Seal (optional)

Now let’s take a closer look at the details:

Step #1: Measure the Area

Measure the height and width of the area where you plan to install the protective barrier, ensuring there’s enough space around the perimeter. When installing a cement board, you need to have accurate measurements to ensure proper coverage.

You’ll need to measure both horizontally and vertically from one end to the other. Make sure to account for any obstacles or irregularities in the surface that may affect how much material is needed.

Step #2: Mark the Cement Board

Marking the panels with a pencil and straight edge is a straightforward process that ensures precise cuts for your protective barrier. Transfer all measurements accurately onto the cement board panels before marking them.

Cut along these marked lines using a jigsaw, circular or tile saw to create individual pieces of cement board.

You should use a level to ensure your lines are straight and even when marking the cement board. This will help prevent any gaps in your heat shield that could allow heat or flames through.

Step #3: Apply Construction Adhesive

Now it’s time to get adhesive-happy and slather that panel with construction glue, ensuring full coverage for optimal protection.

Apply a generous amount of construction adhesive to the back of the cement board panels, covering the entire surface. Ensure the adhesive is evenly distributed so your heat shield works.

When applying the construction adhesive, use a notched trowel or spreader to ensure an even layer.

Step #4: Position the Cement Board

It is now necessary to position the cement board. When positioning the cement board, ensure it’s flush with the wall and level.

Any gaps or unevenness can compromise its integrity as a heat shield. Take your time to ensure proper adhesion and alignment, and always follow manufacturer instructions for best results.

Step #5: Secure the Cement Board

Carefully secure the protective cement board in place using screws that are spaced according to the manufacturer’s recommendations. This will ensure that it stays securely attached to the wall studs and won’t shift or fall off over time.

Also, ensure you don’t over-tighten the screws, as this can cause damage to both the cement board and the wall studs.

When securing the cement board, it’s important to remember that it will act as a heat shield. As such, any gaps or exposed areas could potentially allow heat or flames to penetrate through and reach your home or loved ones.

Step #6: Fill the Joints

Use a putty knife to apply the joint compound on the cement board. Embed joint tape into the joints between cement board panels for proper protection and safety.

Let it dry after applying the joint compound and embedding the joint tape. This step is crucial in filling any gaps or spaces between the cement board panels.

Step #7: Sand and finish

Once you’ve filled the joints and ensured they’re protected, you can sand the surface smoothly with sandpaper and apply any finishing materials.

Use fine-grit sandpaper to carefully smooth out any bumps, ridges, or rough patches on the cement board until it feels completely even to the touch.

Wear a dust mask and eye protection as you work since sanding drywall generates a lot of dust particles that can irritate your lungs and eyes.

Once you’ve finished smoothing the surface, wipe it down with a damp cloth to remove any remaining dust and debris before proceeding with your chosen finish.

Step #8: Paint or Seal (optional)

If you want to enhance the appearance and protect against moisture, consider painting or sealing the surface of your cement board with a heat-resistant product. Once you have sanded and finished your cement board, you can proceed to this optional step.

A heat-resistant paint or sealer will improve the look of your cement board and provide an added layer of protection against potential damage from moisture.

When choosing a paint or sealer, make sure it’s specifically designed for use on surfaces exposed to high temperatures. You need to follow the manufacturer’s instructions carefully when applying the product to ensure proper coverage and adherence.

How much heat can the cement board handle?

This high-density reinforced material can withstand temperatures up to 500°C, making it an ideal choice for protecting against intense heat.

A cement board is often used as a heat shield because it can withstand high temperatures without deteriorating or cracking. Its inorganic fibers help reinforce the cement and prevent it from breaking down under extreme heat.

When placing a cement board as a heat shield, you must use the appropriate thickness for your application. Thicker boards are better suited for higher temperatures and longer periods of exposure, while thinner boards may be suitable for more moderate temperatures.

Protect Your Home: Use Cement Board as a Heat Shield

Heat shielding with cement board is a great way to protect your walls and floors from the intense heat from fireplaces and wood stoves.

You need to follow the above-discussed steps when installing cement boards. Measure and cut it accurately, attach it securely with screws and adhesive, etc.

When handling high temperatures, the cement board can withstand up to 500 degrees Celsius without cracking or warping. But keep in mind that cement boards aren’t fireproof.

Now you can enjoy your heating system with peace of mind using the cement board as a heat shield.